This is my EDC folding/locking blade with hollow ground and serrated blade. Bottle opener and four screwdriver attachments. Orange color to make it an easy find if it ever falls into water, mud or grass.

This is my EDC folding/locking blade with hollow ground and serrated blade. Bottle opener and four screwdriver attachments. Orange color to make it an easy find if it ever falls into water, mud or grass.

View attachment 15677View attachment 15678

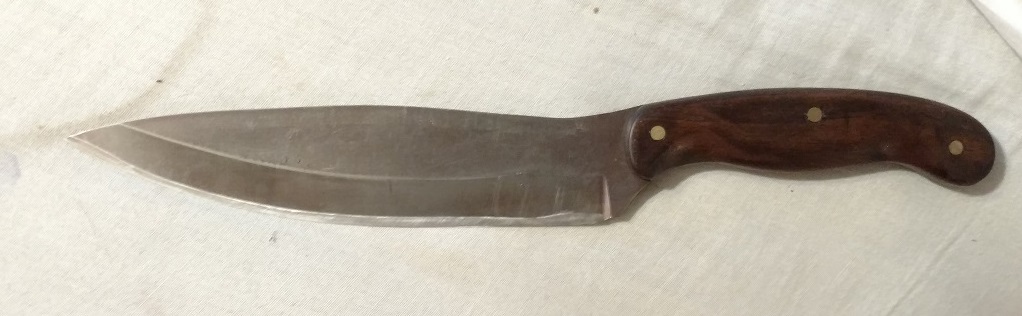

Lovely little knife!While touring a fleamarket, I found this little knife. In Bavaria

i miss my multi tool. Had a gerber, pliers jaw brokeAnother two for one... Work EDC.

I was carrying a Leatherman Wingman, but it got away from me somehow. Replaced it and that one absconded too.i miss my multi tool. Had a gerber, pliers jaw broke

Way back when I was still working I'd buy my employees meaningful items, rather than the safety BS that most managers bought their employees. One year it was a Nikon binoculars, another time it was a travel fishing pole, 1 oz silver coins, and one year it was a Leatherman Wave. I still have mine and use it everyday.I was carrying a Leatherman Wingman, but it got away from me somehow. Replaced it and that one absconded too.

Nice Sod Buster clone.Another two for one... Work EDC.

Nice Sod Buster clone.

Enter your email address to join: