On corrosion resistance...

There historically has been a trade off between several factors in knife steels - Toughness, Edge holding ability, Ease of sharpening, and Corrosion resistance.

First you have to understand that high carbon stainless steel is a composite material and is not homogeneous. It is very much like concrete, where you have hard gravel held in a matrix of softer cement. It is the gravel that makes the concrete wear resistant, but the cement that gives it tensile strength. If you put too much gravel and not enough cement, then it is too brittle and will easily crumble. If you put too much cement and not enough gravel, then it wears away too quickly.

Carbon steel is close to homogeneous with very fine carbides, but when you add carbon for hardness and chromium for corrosion resistance, very hard chromium carbide particles form (gravel in the concrete) decreasing the toughness, and making it difficult to sharpen, but increasing the wear resistance and edge retention. More chromium means more corrosion resistance, but less edge retention. More carbon means better edge retention but less corrosion resistance (because the formation of chromium carbides take chromium out of the steel matrix.

Steels with large carbide particles (such as D2) can give good edge retention but have decreased toughness and are very hard to sharpen. And because so much of the carbon is tied up in the large chromium carbide particles in D2, there is not enough chromium left in the steel matrix to provide much corrosion resistance.

Steels like AEB-L have an expertly designed balance of just enough carbon and just enough chromium so that small carbides form to give excellent toughness, and a balance of edge retention, and corrosion resistance, but it is not as durable an edge as higher carbide steels, and not as corrosion resistant as higher chromium steels.

But if you start with AEB-L and then add nitrogen and vanadium, it improves the edge retention, hardness and corrosion resistance while keeping the small carbides. That steel is called Nitro-V. It still does not have the edge retention of something like D2, but it is much easier to sharpen and holds an edge much much better than the old high chromium stainless steels used for dive knives.

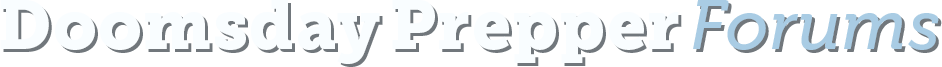

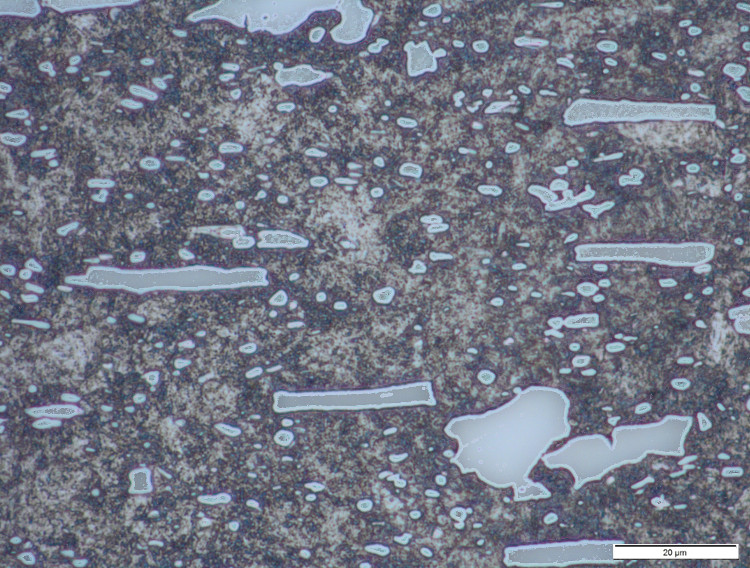

Micrographs of D2 and Nitro-V. The light areas are chromium carbide particles

D2:

Nitro-V